MODEL 3000

DIGITAL CAPACITANCE

METER

Operation and Calibration Manual

Serial Numbers

This manual applies directly

to instruments with serial numbers 30700 and up, and with A0 mainboard PCB

assembly 8503000-0-3.x and 8503000-0-4.x.

Rev. 4.x, 15 December 2021

(Updated 20 October 2024)

Copyright 2021-2024

Serial Number: ___________

For technical assistance, contact

GLK INSTRUMENTS

Email: support@glkinst.com

Website: www.glkinst.com

TABLE OF CONTENTS

|

Section |

|

Page |

|

|

|

|

|

I.

Warranty |

|

3 |

|

|

|

|

|

II. Product Use Restrictions |

|

3 |

|

|

|

|

|

III. Return Material Authorization |

|

3 |

|

|

|

|

|

IV. Specifications |

|

4 |

|

|

|

|

|

V. Description |

|

5 |

|

|

|

|

|

VI. Initial Preparation |

|

7 |

|

|

|

|

|

VII. Operating Instructions |

|

8 |

|

|

|

|

|

VIII. Servicing Information |

|

12 |

|

|

|

|

|

IX. Calibration |

|

14 |

|

|

|

|

|

X. Revisions |

|

15 |

|

|

|

|

|

XI. Options XII. Bias Adapter XIII. Calibration Standard Capacitor |

|

16 18 20 |

|

|

|

|

|

|

|

|

|

|

|

|

I. WARRANTY

GLK Instruments products are warranted against defects in workmanship and materials under normal use and service for one year from date of their shipment by GLK Instruments, except that components obtained from others are warranted only to the extent of the original manufacturers' warranties, if any. This warranty does not extend to any products that have been repaired or altered by others. GLK Instruments' sole liability and the Purchaser's sole remedy under this warranty are limited to repairing or replacing defective products. The repair or replacement of defective products does not extend the warranty period. This warranty does not apply to components or products which by the nature of the applications are consumed in operation or which have a normal life inherently shorter than one year. Examples of this are batteries, components or products exposed to nuclear radiation, or used in the measurement of detection of explosions. GLK Instruments shall not be liable for consequential damages under any circumstances.

THE FOREGOING WARRANTY AND REMEDY ARE IN LIEU OF ALL OTHER REMEDIES AND ALL OTHER WARRANTIES, WRITTEN OR ORAL, STATUTORY, EXPRESS, OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

II. PRODUCT USE

RESTRICTIONS

GLK Instruments does not

recommend the use of any of its products or the incorporation of any of its

products by second parties in their products in (a) life support applications

where failure or malfunction of the product can be reasonably expected to cause

failure of the life support device or to significantly affect its safety or

effectiveness, (b) any nuclear facility applications which including nuclear

reactors and devices designed or used in connection with the handling,

processing packaging, preparation, utilization, fabricating, alloying, storing,

or disposal of fissionable material or waste products, (c) consumer

applications where failure or malfunction of the product can be reasonably

expected to cause injury, and (d) applications where failure or malfunction of

the product can reasonably be expected to place the health and safety of the

general public in jeopardy. GLK Instruments will not knowingly sell its

products for use in such applications unless GLK Instruments receives in

writing satisfactory assurances that (a) the risks of injury or damage have

been minimized, (b) the customer assumes all such risks, and (c) the liability

of GLK Instruments is adequately protected under the circumstances.

III. RETURN MATERIAL AUTHORIZATION

In the unlikely event that any

of the products of GLK Instruments need repair, contact support@glkinst.com for a

return material authorization (RMA) number.

IV. SPECIFICATIONS

(25 oC unless specified otherwise)

Electrical |

|

|

|

Capacitance range: |

|

2.000

pF to 200.0 nF |

|

Resolution: |

|

0.001 pF to 0.1 nF |

|

Display: |

|

3 1/2 digit liquid crystal display (LCD) |

|

Accuracy with or without probes: |

|

±

(0.1% of reading + 2 digits) |

|

Measurement frequencies: |

|

24

kHz (2 pF, 20 pF, 200 pF, 2 nF) |

|

|

|

2.4

kHz (20 nF) |

|

|

|

240

Hz (200 nF) |

|

Charging voltage: |

|

5 V

(all ranges) |

|

Offset adjustment: |

|

1.5

pF |

|

Analog output voltage(1): |

|

0-200

mV (unbuffered) 0-200

mV, 0-2 V, 0-5 V (buffered, option 002) |

|

Analog bandwidth(2) : |

|

1.2

Hz (2 pF), 2.8 Hz (20 pF), 15 Hz (200 pF), 64 Hz (2 nF, 20 nF, 200 nF) |

|

Source resistance: |

|

1000

ohms (1%) |

|

Reference

output voltage: |

|

5.000 VDC |

|

Source resistance: |

|

1000

ohms (1%) |

|

Digital I/O: |

|

USB

Port 1.1 compliant, optically isolated |

|

Battery: |

|

9 V

alkaline (NEDA 1604A) |

|

Auxiliary power: |

|

12 -

14 VDC, 50 mA supply |

|

|

|

with

2.1 mm DC power jack |

|

USB port power requirement: |

|

Isolated,

4.5 VDC to 5.5 VDC, 300mA |

Environmental |

|

|

|

Operating Temperature: |

|

0 oC

to +50 oC |

|

Storage Temperature: |

|

-20 oC

to +70 oC |

|

Operating relative humidity: |

|

80%

(noncondensing) |

Mechanical |

|

|

|

Package: |

|

Bench

top, portable instrument case |

|

|

|

with

tilt bail |

|

Dimensions: |

|

8.50

x 9.52 x2.44 inches |

|

Net Weight: |

|

3

lbs |

Accessories Supplied |

|

|

|

Two miniature

shielded probes and probe accessories (PN 2110112) 9 V

battery (NEDA 1604A) Operation

and Calibration Manual 100

nF Chip Capacitor Battery

eliminator (PN 4001200): input 120 VAC, 60 Hz, 6 W; output 9 VDC, 200 mA; 2.1

mm Plug Application

DVD and USB cable Optional Accessories

International battery eliminator (PN 4001201): input 90 to 264 VAC, 47 to 63 Hz, 18 W, IEC 320 connector; output 12 VDC, 1.5 A, 2.1 mm Plug. Customer supplies AC cord set, 3-prong IEC 320 to local connection. (1) Note: Analog output voltages for

Option 002, Buffered Analog Output Option, are 0–200 mV, 0-2 V, and 0–5 V,

jumper selectable. Option 002 default jumper setting is 0-2 V. (2) Note: Wideband Option 001 increases

bandwidth to ~70 Hz on each range. No additional charge for this option if

specified at time of order. Bandwidth of each range can be customized at time

order. |

||

V. DESCRIPTION

The Model 3000 Digital Capacitance Meter is the first commercially available low cost, high accuracy instrument designed exclusively for the measurement of very small value capacitors and capacitors whose size and shape are not conveniently handled by conventional sockets, clamp fixtures, or alligator clip leads. This instrument is particularly useful for the measurement chip capacitors whose small size precludes the use of identifying marks.

The Model 3000 employs a unique and patented (U.S. Patent No. 4806846) switched capacitor circuit and a ratio metric measurement technique that eliminates errors due to stray capacitance to ground. The patented circuit has high common-mode rejection and eliminates errors due to changes in the reference voltage from temperature, aging, etc. This unique circuit allows the capacitor under measurement to be remotely connected to the meter via two, miniature, shielded probes or coaxial cables without affecting the accuracy or resolution of the instrument.

The

convenience of using miniature probes solves the costly problem of constructing

special test fixtures and shielded boxes for the determination of the

capacitance of a variety of objects. For example, the Model 3000 with its

standard probes can easily determine the capacitance between the pins of a

connector, the large signal gate capacitance of power MOSFETs, the depletion

capacitance of diodes, the capacitance between the traces on a printed circuit

board, or even the static capacitance of microstrip or stripline microwave

circuits. Using ultra-miniature, shielded probes, very accurate wafer level,

large signal measurements of MOS capacitors are easily obtained.

Miniature,

shielded probes are normally supplied with the instrument; however, the Model

3000, due to its unique circuitry, can accommodate a large variety of custom

built shielded probes, special shielded connectors, or test fixtures. Coarse

and fine offset adjustment potentiometers are provided on the front panel of

the instrument to compensate for any unshielded test fixture capacitance up to

1.5 pF. Capacitors can be remotely connected to the Model 3000 using standard

coaxial cables such as RG-223. The Model

3000 maintains its accuracy and resolution with or without probes.

Auxiliary

analog outputs of the LCD meter reading (0-200mV) and reference (charging)

voltage (5.00 V) are available on the back panel. These outputs can be

connected to digital voltmeters, data loggers, computer data acquisition

systems, etc. using standard banana jacks and shielded cables. Option 002,

Buffered Analog Output, provides additional gain to scale the LCD meter reading

by 1X, 10X, and 25X, or 0-200 mV, 0-2 V, and 0-5 V, respectively.

Fully

isolated digital I/O is available at the USB port on all new instruments

starting at serial numbers 30024 and up. Older instruments can be upgraded to

support digital I/O for a nominal charge. Contact sales@glkinst.com for details. The USB port provides access to the

instrument’s 24-bit ADC and range switches.

Digital I/O support extends the resolution and range of the instrument

as shown in Table I.

A

standard 9 V alkaline or lithium battery powers the Model 3000. Battery life is

approximately 200 hours. An auxiliary DC

power jack is provided for powering the instrument from the battery eliminator

(US version PN 4001200 or optional, international version PN 4001201). The USB port can also supply isolated power

to the Model 3000. The USB cable must be connected to a compliant USB port

(powered port) on the host computer. When powered by the USB port, the Model

3000 is always on, independent of the ON/OFF switch position. Due to the optical and magnetic isolation of

the USB port from the Model 3000 circuitry, the USB port is active only when

powered from the host computer.

Table

I. Extended Range and Resolution at USB Port

|

Front Panel |

USB Port |

||

|

Range Switch |

3 ˝ Digit LCD Meter |

Extended Range |

Extended Resolution |

|

2 pF |

1.999 pF |

3.0000 pF |

0.1 fF |

|

20 pF |

19.99 pF |

30.000 pF |

1 fF |

|

200 pF |

199.9 pF |

300.00 pF |

10 fF |

|

2 nF |

1.999 nF |

3.0000 nF |

0.1 pF |

|

20 nF |

19.99 nF |

30.000 nF |

1 pF |

|

200 nF |

199.9 nF |

300.00 nF |

10 pF |

VI. INITIAL PREPARATION

The Model 3000 (PN 2903000-0) is supplied ready for use with a battery, battery eliminator, two probes with accessories, USB cable, and application CD with USB port drivers and LabVIEW demonstration programs. If a 9 V battery is not installed, open the battery compartment cover on the back of the instrument by removing the two thumbscrews. Connect a 9 V battery to the polarized snap lead, clamp the battery to the cover, replace cover, and secure with thumb screws. If the instrument is to be stored for an extended period, remove the battery to prevent damage from leakage.

*********************************************************

ALWAYS DISCONNECT THE BATTERY ELIMINATOR AND

ANY TEST FIXTURES OR PROBES FROM THE INSTRUMENT WHEN REPLACING THE

BATTERY. BEWARE OF STATIC ELECTRICITY

*********************************************************

The

instrument is now ready for use; however, it is recommended to perform the following

initial checkout to become more familiar with the instrument. Select the 2.000

pF range by depressing the respective front panel switch. Turn on the

instrument by pressing the ON switch. The liquid crystal display should appear

and settle to a stable reading of ± 0.002 within a few seconds. The instrument

was adjusted at the factory to read ± 0.002

pF. If the display is not within ± 0.002 pF, then adjust the “OFFSET ADJ COARSE

FINE” potentiometers on the front panel of the instrument. Unpack the two

probes, and connect each probe to the front panel BNC connectors. Hold probes

at least 6 inches apart and observe the display. The display should read ±

0.002 pF provided the probes are held stationary. If necessary, adjust the

OFFSET FINE potentiometer to zero the display. Hold the probes tips about 1/10

inch apart. You should observe a reading of approximately 0.015 pF or 15

femtofarads. Place the probes at least 6 inches apart again and check the zero

on the other ranges by depressing each range switch while observing the

display. Next, measure a 100 nF chip capacitor supplied with the unit. First

select the 200 nF range; second touch each of the metalized ends of the chip

capacitor with the probe tips; and third, read the display. The 100 nF chip capacitor

has tolerance of ± 20%.

*******************************************************

CAUTION - ALWAYS DISCHARGE HIGH VOLTAGE

CAPACITORS BEFORE MEASURING TO AVOID DAMAGE TO INSTRUMENT

*******************************************************

You should now be familiar with the general use of the Model 3000 Digital Capacitance Meter. For a more detailed discussion of the operation of the Model 3000, refer to the following section.

VII. OPERATING INSTRUCTIONS

A detailed description of each function of the instrument is given in this section. The basic functions of the Model 3000 are listed below.

Front Panel:

1)

Display, 3 1/2 digit LCD

2)

Range switch, 2 pF to 200 nF, push-to-select

3)

Power switch, push-ON, push-OFF

4)

Cx HIGH input BNC (positive connection,

drive)

5)

Cx LOW input BNC (negative connection,

sense)

6)

OFFSET ADJ COARSE FINE potentiometers

Rear panel:

7)

9 V battery compartment

8)

Auxiliary DC power jack

9)

Analog output jacks, 0-200 mV (Option 002, 0-200 mV, 0-2 V or 0-5 V)

10)

Reference voltage output jacks, 5.00 V DC

11)

USB port

1) The

display is a self-contained 3 1/2 digit LCD digital voltmeter with polarity and

decimal point

indication. The decimal point is automatically selected when the desired range

switch is pushed.

2) The range

switch is a push-to-select interlocking assembly. Ranges are 2 pF, 20 pF, 200

pF, 2 nF, 20 nF, and 200 nF. A resolution of 0.001 pF or 1 femofarad can be

achieved on the 2 pF range.

3) The power

switch is a push-ON and push-OFF type. Note: when powered by the USB port, the

Model 3000 is always on independent of the ON/OFF switch position.

4 & 5) Connection to the Model 3000 is via the

BNC's on the front panel. Normally the probes supplied with the instrument will

be connected to these terminals. However, custom-built shielded probes,

connectors, or other special test fixtures can be connected to these terminals

without affecting the accuracy of the instrument. The terminal marked (+) or

HIGH is the positive drive or charging terminal and should be connected to the

positive terminal of polarized capacitors. Likewise, the negative sense terminal

(-) or LOW input should be connected to the negative terminal of polarized

capacitors. The HIGH terminal should always be connected to the outer foil,

plate, or larger electrode of the capacitor under measurement and the LOW

terminal to its other electrode to minimize noise pickup. In the case of

3-terminal capacitors, such as calibration standards, the shield of the

capacitor (i.e. its third electrode) should be connected to the ground shield

of the probes. An alternative is to connect a 3-terminal capacitor to the

instrument using coaxial cables. In electrically noisy environments the

capacitor under test may require shielding to obtain a stable reading. To

maintain accuracy and obtain low noise readings, connect external shielding to

both probe shields.

The Model 3000 uses a combination of CMOS and JFET devices to charge and discharge the capacitor under test; consequently, voltage transients can damage these devices and will cause the instrument to malfunction. All capacitors, but specifically high voltage and high capacitance capacitors, must be discharged first before measurement to avoid damage to the instrument.

**********************************************************

DISCHARGE ALL CAPACITORS BEFORE MEASUREMENT

TO PREVENT DAMAGE TO THE INSTRUMENT AND TO PREVENT PERSONAL INJURY

**********************************************************

The drive level that is presented to the capacitor under test from the (+) or HIGH connection is +5.00 V peak with respect to the (-) or LOW connection or to ground (shields); thus, a wide range of capacitors that have breakdown voltages as low as 5 V can be measured with the Model 3000 without damaging the capacitor under test. Avoid capacitors that have leaky dielectric or high conductance. The Model 3000 cannot measure conductance. Depending on the range, leaky dielectric capacitors can produce erroneous readings. Likewise, the depletion capacitance of diodes must be measured under reverse bias conditions, i.e. HIGH terminal is connected to the cathode, and the LOW terminal is connected to the anode to reverse bias the diode.

6) The

“OFFSET ADJ COARSE FINE” potentiometers on the front panel of the instrument

are used primarily to compensate for the capacitance between the unshielded

terminals of test fixtures used to measure axial and radial leaded capacitors.

The OFFSET potentiometers can subtract up to 1.5 pF of test fixture

capacitance. The OFFSET potentiometers are used also to zero the instrument on

the 2 pF scale and may be required occasionally due to amplifier drift,

component replacement, or operation at elevated temperatures.

7) A 9 V battery is housed in a compartment on the

rear of the instrument. The Model 3000 will operate for approximately 200 hours

on a 9 V alkaline battery. A low dropout voltage regulator allows extended use

of the battery down to a voltage of about 6.2 V before replacement.

8) The auxiliary

DC power jack provides the capability of operating the instrument continuously

from an external power source such as the battery eliminator (PN 4001200). The

internal 9 V battery is automatically disconnected from the instrument when the

battery eliminator is connected.

9) The analog

output jacks provide a 0-200 mV DC signal proportional to the capacitor value

under test. Option 002, Buffered Analog Output, provides additional gain to

scale the LCD meter reading by 1X, 10X, and 25X, or 0-200 mV, 0-2 V, and 0-5 V,

respectively.

The bandwidth of the analog output signal is

range dependent as shown in Table II. The source resistance of the analog

output is 1000 ohms.

Table II. Analog

Bandwidth

|

Range |

Measurement Frequency (Hz) |

Bandwidth (Hz) (Standard) |

Bandwidth (Hz) (Option 001) |

|

2 pF |

24,000 |

1.2 |

67 |

|

20 pF |

24,000 |

2.8 |

71 |

|

200 pF |

24,000 |

15 |

78 |

|

2 nF |

24,000 |

64 |

79 |

|

20 nF |

2400 |

64 |

79 |

|

200 nF |

240 |

64 |

79 |

10) The internal 5 V DC reference voltage is available

at the reference output jacks. Its source resistance is 1000 ohms. The

reference output voltage is used to provide external ratio metric capability to

remove errors in the analog output signal due to changes in the reference

voltage from temperature and long term drift. For ratio metric measurements,

connect the 5 V reference output to the external reference input on digital

voltmeters, data loggers, etc. that provide for this option. Alternatively, errors

from variations in the reference voltage can be removed from the analog output

signal by calculating the ratio of analog output to the 5 V reference output

and multiplying by the appropriate scale factor. Using the external outputs of

the Model 3000 with precision digital voltmeters or data acquisition systems,

capacitors can be measured to greater precision and to a resolution of

approximately 10 ppm (range and bandwidth dependent).

11) USB port provides fully isolated digital I/O and

power, extended resolution and range as shown in Table I, and powers the Model

3000 from the host computer. To access the USB port, the appropriate drivers

must be installed on the host computer. The drivers are available on the

application DVD-ROM or can be down loaded from our website at: www.glkinst.com/cmetersoftware. To install the USB drivers on the host computer,

follow the instructions in the file: ReadmeUSBDriverInstall

To demonstrate the basic

features of the Model 3000 digital I/O, load and run the LabVIEW® demonstration

program. This program is available as a standalone application or VI. The

demonstration programs are written for various versions of LabVIEW® and complied

with National Instruments' (www.ni.com) Application

Builder. Users without LabVIEW® can run the application by installing the

LabVIEW® runtime engines included on the Model 3000 application DVD-ROM.

Note: All

software and drivers for the Model 3000 have been tested only on computers

running Microsoft's Windows XP®, Windows 7®, and Windows 10®. To completely

install all USB drivers, “found new hardware” may run four times in Windows

XP®. All of the Model 3000 and USB communication VI's were written initially in

LabVIEW® 7 and been verified for later versions of LabVIEW®. The software will

probably fail to run in versions of earlier than LabVIEW® 7. Contact National

Instruments, www.ni.com, to upgrade to

version 7 or later; or install the appropriate version of the LabVIEW® run time

engine and run the executable version of the demonstration program.

VIII. SERVICING INFORMATION

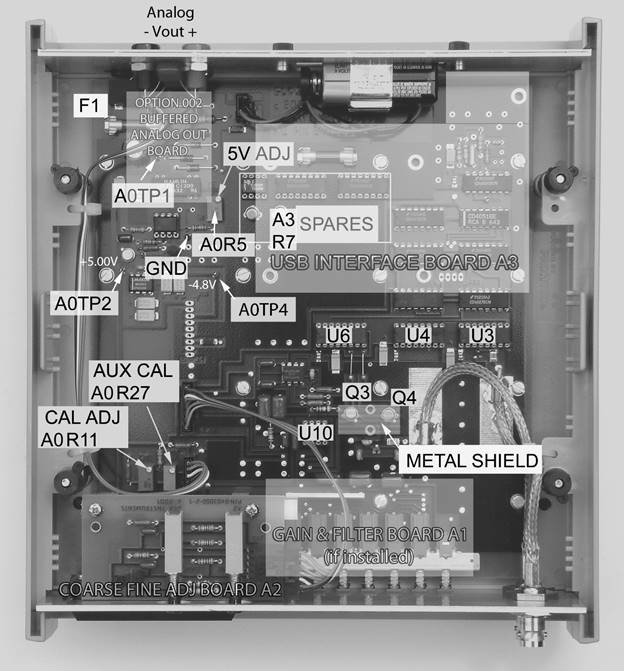

For service and calibration of the Model 3000 Digital Capacitance Meter, contact support@glkinst.com directly. Complete repair and calibration services are maintained by GLK Instruments; however, minor repair and calibration can generally be performed in the field if you have access to a precision 3-terminal capacitor standard. Location of parts, test points, and adjustments are shown in Figure 1.

The capacitor measuring technique in the Model 3000 uses a switched capacitor circuit consisting of two JFET transistors driven by CMOS logic and a convert current to voltage circuit with low pass filter. Input protection from voltage transients is built-in to the switched capacitor circuit; however, failure to discharge high voltage capacitors or static discharge can damage the circuitry. The switched capacitor circuit includes these replaceable parts Q3 and Q4 (2N5116 JFETS), U3, U4, and U6 (4049 CMOS hex buffers), and U10 (TL061 opamp).

In the event that the switched capacitor circuit is damaged, spare parts are located inside the Model 3000 on the main board, A0, below the ADC-digital I/O board (USB interface), A3, if present. The spare parts include 2-each, 2N5116 JEFTS (Q3 and Q4), 2-each 4049 CMOS hex buffers (U3, U4, or U6), 1-each TL061 opamp (U10), and 1-each 0.125 A fuse (F1) for the external power supply or battery eliminator. All critical parts are socketed for easy replacement. JFETS, Q3 and Q4, should be replaced in pairs.

Basic

Diagnostics:

If the Model 3000 fails to power on under battery power, replace the 9 V battery through the compartment on the back of the instrument. Remove the two thumbscrews to gain access to the battery. If the Model 3000 fails to power up when connected to the battery eliminator but operates normally on battery power, check the battery eliminator for approximately 12 V between the center pin and outer conductor and fuse, F1. Replace battery eliminator if defective. To check fuse, open the Model 3000 by removing the four screws on bottom of the instrument and remove the top cover. Check fuse with an ohmmeter and replace if open using the spare fuse. If the Model 3000 still fails to power on, contact support@glkinst.com.

If you suspect that the input circuitry is damaged, first check regulated power supply voltage between A0TP2 and GND for a voltage of 5.000 ± 0.005 V. Check the negative supply voltage between A0TP4 and GND for a reading of -4.8 ± 0.5 V. If proper readings are obtained, proceed to the next step. Check that a 0 to 5 V square wave is present at the “HIGH” BNC terminal on the front panel. If there is no signal, replace U3 and U4; recheck for square wave. JFETS, Q3 and Q4, are located inside the rectangular metal shield. To gain access to Q3 and Q4, remove the two, 2-56 nuts on the top of the metal shield. Replace both Q3 and Q4, and zero the LCD meter using the coarse and fine adjustments. If unable to zero, replace U10 adjacent to Q3 and Q4. Repeat zero adjustment. Attach a 1 nF standard capacitor (P/N 2901409-102), and note the LCD reading. If the reading is 1.00 ± 0.02 nF, the Model 3000 is working correctly. Replace the metal shield and calibrate instrument. If the above repair is unsuccessful, the instrument will need factory service. Contact support@glkinst.com for RMA and shipping instructions.

Figure 1. Location of parts, test points, and

adjustments. Spares are located on the

mainboard A0 near the battery. If the USB interface board A3 is installed,

remove 5 screws and lift A3 out of the way to gain access to the spares.

IX. CALIBRATION

Field calibration of the Model 3000 Digital Capacitance Meter can be accomplished using only a single 1.000 nF (1000 pF), 3-terminal standard capacitor such as General Radio or IET Labs (www.ietlabs.com) Model 1404-A standard reference capacitor. Refer to main circuit board, A0, and ADC-digital I/O board (USB interface), A3, for the location of test points and calibration adjustments. Adjustments and test points are labeled on the printed circuit boards (see Figure 1).

To calibrate the Model 3000, first remove the top half of the instrument case by removing the four screws located in the bottom half of the case. If operating in battery mode, check the battery voltage at A0TP1. If its voltage is below 7 V, replace the battery with a fresh 9 V alkaline or lithium cell. The Model 3000 should function correctly down to a battery voltage of approximately 6.2 V. Note, in the following procedure, the calibration standard is assumed to 1.0000 nF ± 0.0001 nF. Your standard may differ slightly in value; in that case, adjust the Model 3000 meter reading to agree with your standard.

Turn on the

instrument, measure the voltage at A0TP2, and adjust the 5 V potentiometer,

A0R5, to set the voltage at A0TP2 to +5.000 ± 0.005 V. Select the 2.000 pF

range and adjust the OFFSET COARSE and FINE potentiometers to zero the display.

The display should read ± 0.000 pF after zero adjustment. Select the 2.000 nF

range and connect the 1.000 nF (1000 pF) standard capacitor to the instrument

using coaxial cables. Adjust the CAL potentiometer, A0R11, for a display

reading of 1.000 nF ± 0.000 nF.

Connect a

calibrated, high impedance voltmeter, such as the Agilent 34401A, to the ANALOG

OUTPUT terminals on the back of the instrument. The 34401A should be set as

follows: range to 200 mV, resolution to fast 6-digit, and input resistance to

>10 Gohm. Adjust the AUX CAL potentiometer, A0R27, for a reading of 0.1000 V

± 0.0001 V. If option 002, Buffered Analog Output, is installed and is set to 2

V (default) or 5 V output range, adjust A0R27 for a reading of 1.000 ± 0.001 V

or 2.500 ± 0.003 V, respectively.

Connect the

Model 3000 USB port to the host computer and run the Model 3000 LabVIEW®

demonstration program. Adjust AD CAL potentiometer, A3R7, for a software

display reading of 1.0000 nF ± 0.0001 nF. A3R7 is located on the USB interface

board in the approximate position shown in Figure1.

This completes

the basic calibration of the instrument. All of the other ranges will track the

calibration on the 2.000 nF range to within ± (0.1% of reading + 2 digits).

Remove the standard capacitor and replace the cover. The Model 3000 is now

ready for use as precision capacitance meter.

X. REVISIONS

The

following changes are effective for instruments with serial numbers 30000 and

up (PCB Assembly 8503000-0-3 Rev 3 and up).

The

5 V adjustment (A0R5) was eliminated on instruments beginning with serial

number 31714 through 31725 and with PCB assembly 853000-0-3.3, 853000-0-3.5,

and 853000-0-3.6. The 5V reference

adjustment (A0R5) has been re-instated on instruments starting with serial

number 31726 and up and with PCB assembly 853000-0-3.7 and up.

A

pre-regulator was added on instruments beginning with serial numbers 31736 and

up with PCB assembly 853000-0-4.x.

This manual and any future revisions

will be posted on our website: www.glkinst.com

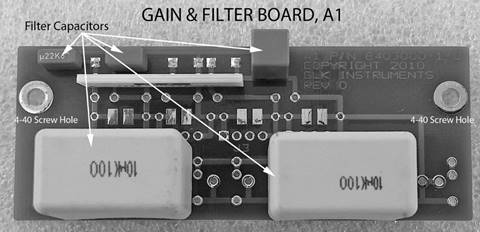

XI. OPTIONS

Option

001 Wideband Analog Output

Wideband

Analog Output Option 001 increases the instrument’s bandwidth at the Analog

Output terminals to approximately 70 Hz on each range. The bandwidth of the

instrument is determined primarily by the values of the capacitors on Gain

& Filter board A1 shown in Figure 2 and by components on the A0

mainboard. To achieve full bandwidth

offered by Option 001, the option needs to be requested at time of order. It is

not a field installable option. To install Option 001 in instruments that

shipped with the standard bandwidth board A1, the instrument must be returned

to GLK Instruments to make the

necessary component changes on the A0 mainboard and to re-calibrate the

instrument. The bandwidth can be customized if full 70 Hz is not required by

replacement of the Gain & Filter board A1 only. Contact support@glkinst.com for details.

Figure 2. Gain

& Filter board A1. The location of the 4-40 screw holes used to secure it

to the A0 mainboard are shown on the left and right side of the board.

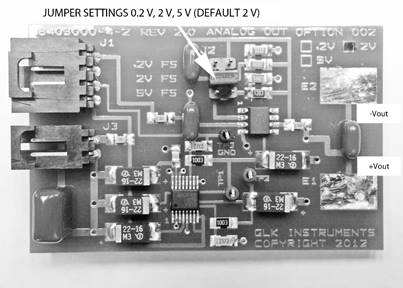

Option 002 Buffered Analog Output

The

analog output banana jacks provide an unbuffered 0-200 mV DC signal

proportional to the capacitor value under test. Option 002 inserts an

adjustable gain stage in the signal path between the unbuffered output and the

banana jacks. The gain is jumper selectable and can be set to scale the LCD

meter reading by 1X, 10X, and 25X, or 0-200 mV, 0-2 V, and 0-5 V, respectively.

Unless specified otherwise, the default setting is 10X or 0-2V output range as

shown in Figure 3. The output resistance

is 1000 ohms.

NOTE: Option 002 is not a field installable. Contact support@glkinst.com for details.

Figure 3. Option 002 Buffered Analog Output jumper

settings. Default setting is 2V FS (0-2 V output).

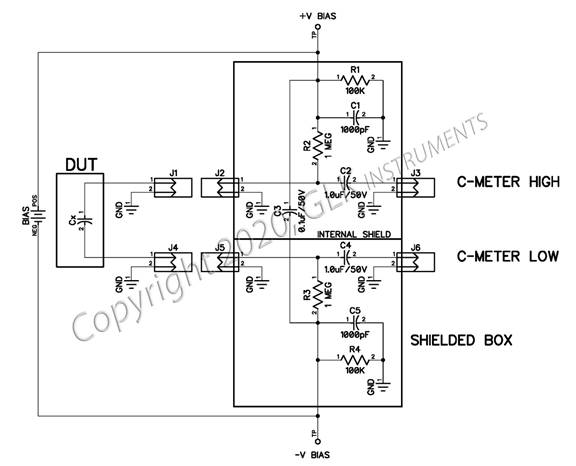

XII. Bias Adapter

The

bias adapter (P/N 2901500-000) shown in Figure 4 is designed to operate with

the Model 3000 Capacitance Meter for device characterization under DC voltage

bias. By connecting an external DC voltage source to this adapter, a bias

voltage of up to +/- 50 V can be supplied to the capacitor or device under test

(DUT).

Figure 4. The image of the bias adapter shows the BNC

connections to the DUT (Cx) and Model 3000 High/Low terminals. The external

DC voltage bias is applied to the DUT through the red (+) and black (-) banana

jacks (standard 0.750 inch spacing).

The

schematic of the bias adapter is shown in Figure 5. DC bias is supplied through 1.0 megohm

resistors R2 and R3 to the DUT. The 1.0 µF capacitors C2 and C4 isolate the

meter from the bias. The DUT or test capacitor Cx is in series with

C2 and C4. The actual reading (Cmeter) will be reduced by the series

connection of Cx, C2, and C4:

Cmeter = 1 / (1/Cx

+ 1/C2 + 1/C4)

or

Cx = 1 / (1/Cmeter

- 1/C2 - 1/C4)

For

example, if Cx is equal to 1.00 nF, the meter reading will be

Cmeter = 1 / {1/(1.0e-9) +

1/(1.0e-6) + 1/(1.0e-6)} = 0.998 nF

Figure 5. The schematic of the

bias adapter shows the connections to the DUT (Cx), DC voltage bias,

Model 3000 Capacitance Meter, and component values.

NOTE: When using the bias

fixture, the settling time required to reach stable readings increases due to

the values of the bias resistors and capacitors. Up to several seconds maybe

required between bias voltage changes to reach steady state reading.

XIII.

Calibration Standard Capacitor

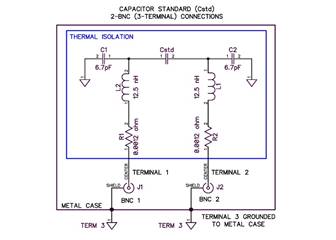

A 1.0 nF capacitor standard (P/N

2901409-102) is available for the Model 3000 Capacitor Meter (Figure 6). Each

calibration standard capacitor ships with a certificate of calibration and two

coaxial cables. The calibrated value and serial number of the capacitor

standard is printed on the case of each unit.

Generally, only the 2 nF range on the

Model 3000 Capacitance Meter needs to be checked with the 1 nF capacitor

standard to verify correct operation of the meter. If verification of other

ranges is needed, we offer capacitor standards of 10 pF, 100 pF, 10 nF, and 100

nF under part numbers 2901409-100, 2901409-101, 2901409-103, and 2901409-104,

respectively. The capacitor standards are also available as a set of five

standards, part number 2901409-SET (Figure 7).

Figure 6. Calibration Standard Capacitor and equivalent circuit. Standard

is supplied with two coaxial cables for remote connection to the Model 3000

Capacitance Meter.

Figure 7. Calibration Standard

Capacitor Set, part number 2901409-SET. The five standards are supplied with

fitted box, two coaxial cables for remote connection to the Model 3000

Capacitance Meter, and certificate of calibration.